Elinvar-like effect induced by high lattice distortion in Zr6Ta2O17 ceramics

Seeking an excellent balance of stiffness, strength, and toughness has become a research hotspot of structural materials. However, only high strength and high toughness are not enough for thermal barrier coatings materials (TBCs). The rapid loss of mechanical properties at high temperatures is a key factor in determining its service life.

It is well known that some shape memory alloys have attracted extensive attention due to their elastic stability (Elinvar effect) at high temperatures. This insensitivity of elasticity to temperature is generally attributed to spontaneous volume magnetostriction or magnetic exchange energy. Unfortunately, ceramic materials with the Elinvar effect have not yet been reported.

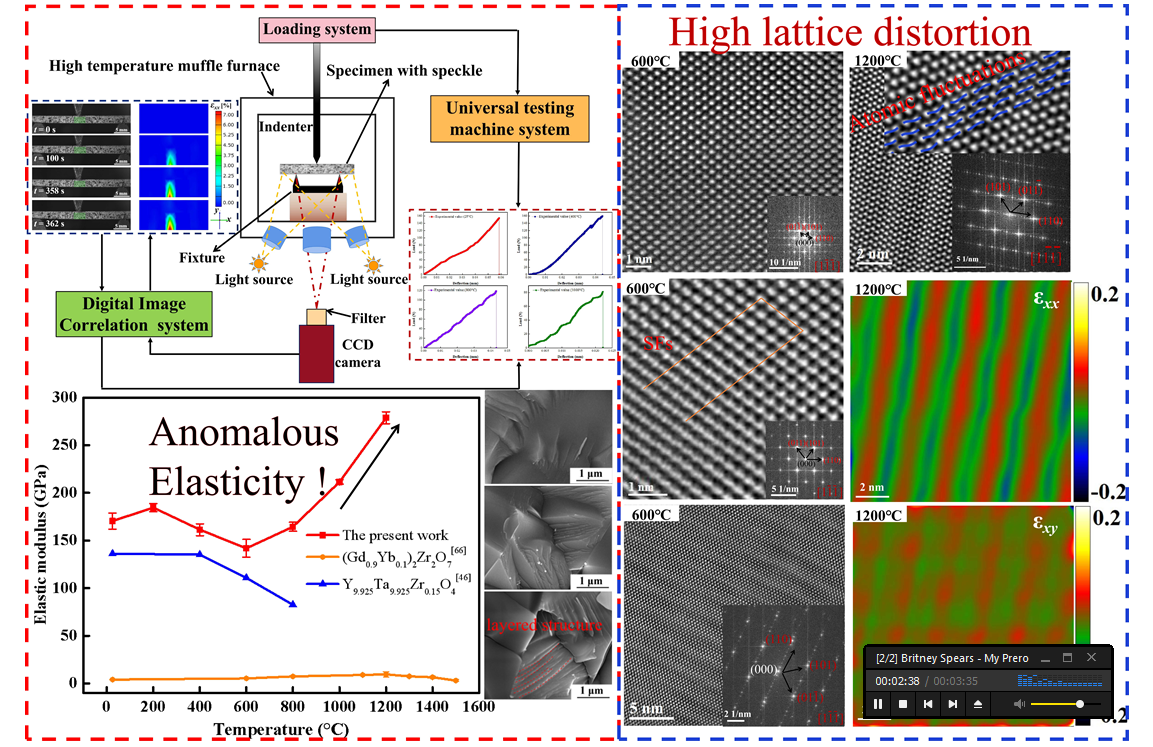

A research team from Xiangtan University discovered a kind of ceramic material with Elinvar-like effect. Based on the three-point bending test platform combined with digital image correlation technology, the deformation behavior of Zr6Ta2O17 ceramics with high configuration entropy at 25 ~ 1200 °C was monitored in situ. The correlation between elastic modulus and temperature shows an abnormal growth trend, as shown in the Figure. The study was published today (Aug. 5) in Research, the first Science Partner Journal recently launched by the American Association for the Advancement of Science (AAAS) in collaboration with the China Association for Science and Technology (CAST). Wang Zhu is a professor of College of Materials Science and Engineering, Xiangtan University.

The team's research results confirmed that its abnormal elasticity is not due to the change of the second-order phase transition or fracture mode of ordinary ferroelastic ceramics. Therefore, the abnormal phenomenon of elastic modulus and fracture strength of Zr6Ta2O17 ceramics at high temperature is likely to be due to structural changes at the atomic scale, even if there is no significant difference in the overall fracture mode.

The team used high-resolution transmission electron microscopy (HRTEM) and aberration-corrected scanning transmission electron microscopy (AC-STEM) to study the atomic-scale microstructure of the fracture at different temperatures. The results exhibit that the lattice structure undergoes high lattice distortion, stable twins and stacking faults appear under the action of stress and temperature, and even the atomic arrangement presents an 8-fold periodic ordered atomic structure similar to the long-period structure modulation (LPSO) observed in some strengthened alloys or ordered superstructure modified parent phase structures. Surprisingly, the atoms show unprecedented orderly fluctuations as the temperature further increases.

Therefore, the Elinvar-like effect of Zr6Ta2O17 ceramics can be attributed to the high distortion of lattice structure and the change of atomic-scale chemical order under the simultaneous action of stress and temperature.

In order to explore the related contribution of stress and temperature in abnormal elasticity, the team adopted the method of controlling a single variable to study its influencing factors. The results confirmed that stress is the main factor leading to lattice distortion of Zr6Ta2O17 ceramics, and temperature can further improve the lattice distortion and atomic-scale chemical order of Zr6Ta2O17 ceramics.

“The unique structural characteristics of Zr6Ta2O17 ceramics make it have excellent dislocation motion energy barrier, excellent deformation resistance and Elinvar-like effect. At high temperature, the structural disorder is further reduced due to the chemical order transformation and atomic fluctuation of all grains, resulting in a further increase in the elastic modulus. In addition, the special crystal structure helps to improve mechanical properties, including plasticity and strength, indicating that Zr6Ta2O17 ceramics can maintain excellent performance at high temperatures. As far as we know, these properties are unparalleled compared to traditional ceramics and even reported alloys. This unique high-temperature strengthening ceramic has potential application prospects in high-performance protective materials, especially new TBCs working at higher temperatures (> 1400°C) in high-thrust aero-engines. ” Zhu said.

This work was supported by the National Natural Science Foundation of China (grant no. 12372102), the Science and Technology Innovation Program of Hunan Province (grant no. 2022RC1082), the Scientific Research Foundation of Hunan Provincial Education Department (grant no. 21A0120), and Postgraduate Scientific Research Innovation Project of Hunan Province (grant nos. XDCX2021B139, CX20230551, and CX20220559). Graduate student Xiaopeng Hu and Qing Liu served as the paper’s co-first authors.

Tag: Advanced Materials

Sources: https://spj.science.org/doi/10.34133/research.0436